Programmable Logic Controller Trainers PLC-FPO30Description

The EDU-LABS Programmable Logic Controller Trainer PLC-FPO30 are powerful and flexible systems ideally suited to your specialized needs. Panasonic’s NAIS is a leader in industrial automation and many factories commonly use their products. The systems in our trainers are compatible with a variety of accessories and peripherals, thus allowing them to be easily expanded into larger systems. This trainer is suitable for the students to develop competence in operating, programming, and troubleshooting modern PLC control circuits. Several models of trainers are available in different sizes. These trainers are Basic Training Package, intermediate training package and advanced training package according to their difficulty level and equipments needed. A student experiment manual is provided to guide the student through the experiments. The experiments are chosen to cover the topics from basic familiarization of the PLC up to programming and applications.

SPECIFICATIONS

o PLC module built-in 16 inputs and 14 outputs Binding Post socket for external interface

o PLC module NAIS FPO-C14RS with built-in standard of 8 inputs and 6 outputs

o Expansion module NAIS FPO-E16RS with built-in expansion of 8 inputs and 8 outputs

o Programming port RS232C with programming cables

o 12VDC & 24VDC Power Supply Module

o 8 integrated input toggle switches

o 8 integrated input Push To ON switches

o 16 integrated input Pilot lamp indicators

o 14 integrated output Pilot lamp indicators

o 24VDC Motor Module

o 24VDC Buzzer Module

o Input & Output Voltage Polarity Module

o 47 integrated Binding Post Socket for:

o 16 inputs

o 14 outputs

o 2 points of 24Vdc

o 2 point of 12Vdc

o 4 points of 0V

o 5 points of Relay

o 2 points of Motor

o 2 points of Buzzer

o Operation voltage: 240 VAC, 50Hz, 5A Fused Protected

SOFTWARE

• PLC Programming Software (Student Evaluation Version)

ACCESSORIES

• USB to RS-232C Programming Cable

• Manual in CD complete with examples sample programs

• 4mm Stackable Test Lead Sets

• AC Power Cord

DOCUMENTATION

• To supply hardcopy and softcopy of the Instruction & Experiment Manual.

PROGRAMMING EXAMPLES

o Example 1: Utilization of Toggle Switch and Push Button

o Example 2: Utilization of Counter and Buzzer.

o Example 3: Utilization of Delay-ON Timer , Internal Relay and Motor

o Example 4: Utilization of Timer

o Example 5: Traffic Lights Control Simulation

- Description

Description

Experiments Modules

1. Automatic Washing Machine Experiments Module : PLC-EM01

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of automatic washing machine.

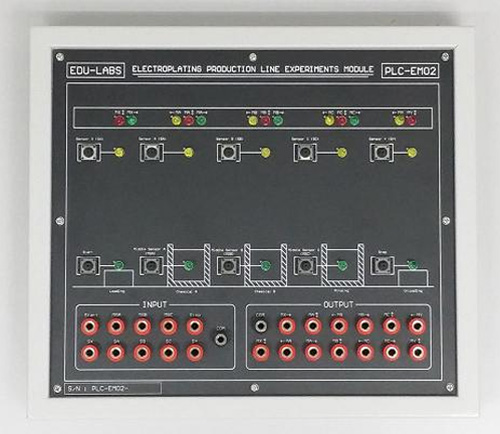

2. Electroplating Production Line Experiments Module PLC-EM02

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle Electroplating Production Line control system.

3. Stepper Motor Control Experiments Module PLC-EM03

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Stepper Motor Control.

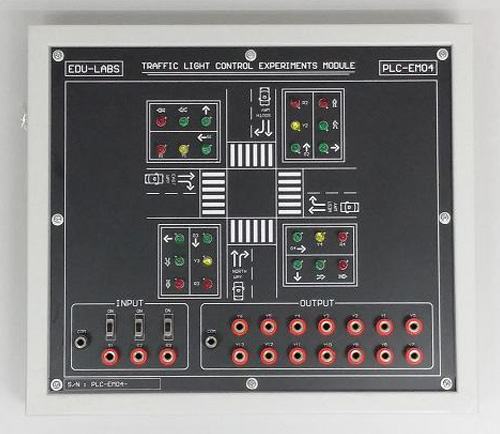

4. Traffic Lights Automatic & Manual Control Experiments Module PLC-EM04

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Traffic Light Control system.

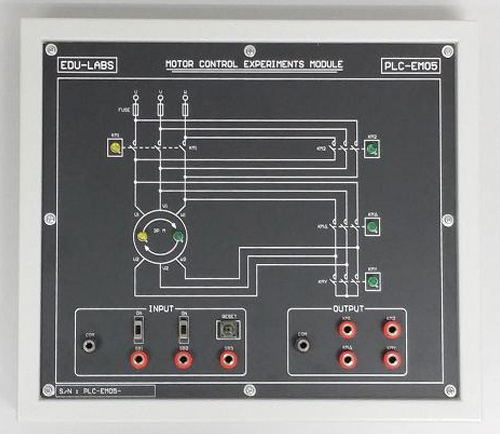

5. Motor control Experiments Module PLC-EM05

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. Learn 3-phase motor start method by using PLC-FPO30 & PLC-EM05.

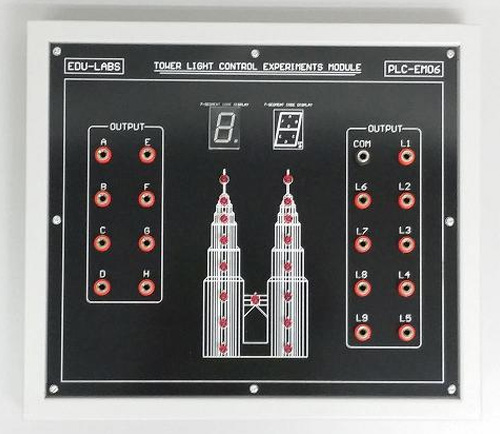

6. Tower Lights Control Experiments Module PLC-EM06

Experiment purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Tower Light Control system.

7. Vehicle Automatic Feeding & Loading Experiments Module PLC-EM07

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of automatic feeding and loading control.

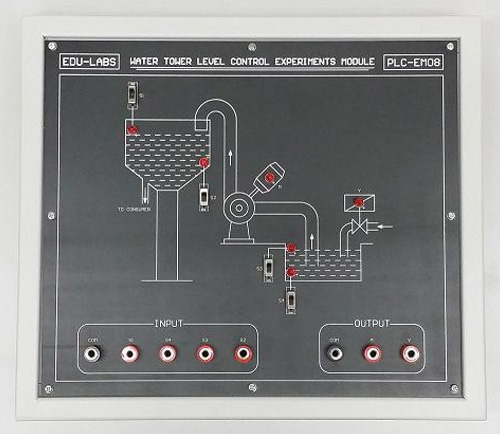

8. Water Tower Level Control Experiments Module PLC-EM08

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Water Tower Level Control.

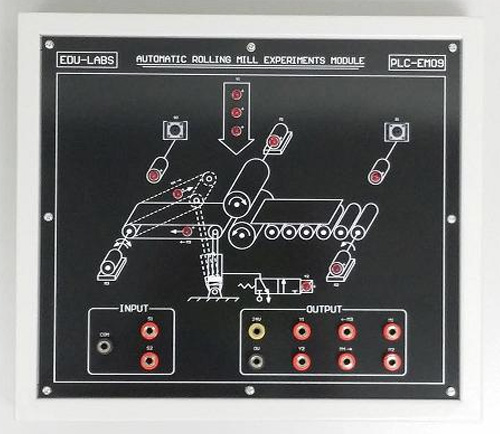

9. Automatic Rolling Mill Experiments Module PLC-EM09)

Experiment purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Automatic Rolling Mill.

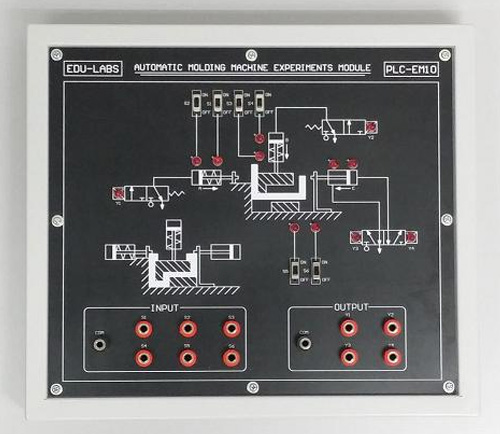

10. Automatic Molding Machine Experiments Module PLC-EM10

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Automatic Molding Machine.

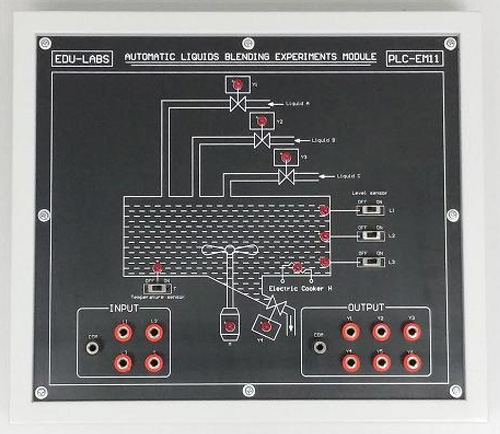

11. Automatic Liquids Blending Experiments Module PLC-EM11

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of Automatic Liquids Blending.

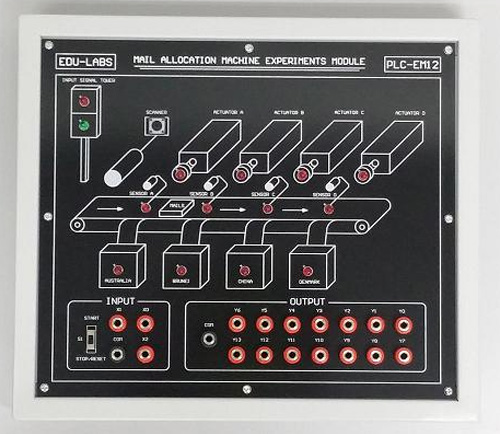

12. Mails Allocation Machine Experiments Module PLC-EM12

Experiment Purpose:

1. To understand and familiarize the application of Programmable Logic Control (PLC) in automation system by using simulation method.

2. To understand the operation of mail allocation machine

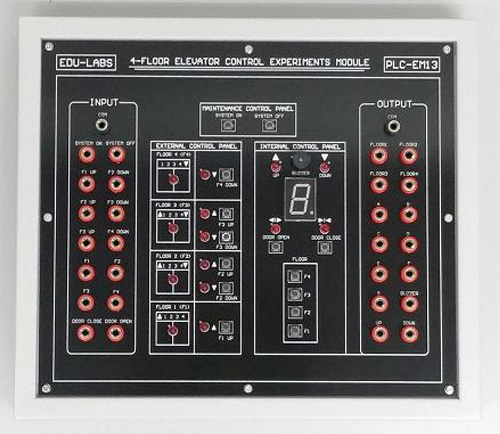

13. 4-Storey Elevator Control Experiments Module PLC-EM13

Experiment Purpose:

1. To understand and capable of utilizing programmable logic controller to perform control system.

2. To understand the working principle of elevator.

Note : These trainer’s layout & specifications are subject to change without prior notices.