Hydraulics & Electro-Hydraulics Trainers (Water Base) FW-202Description

- Description

Description

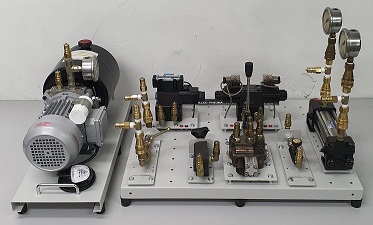

The FW-202 is consists of actual industrial grade modified aluminum pneumatics parts which are commonly apply and used in industrial field. It is classified into basic level, intermediate level and up to advance level training experiments.

It is easily customizable in modular format for the logical analysis of electrics circuits, design and wiring in hydraulics and electro-hydraulics training experiments, which is included electric control for hydraulics sequence control. The expansion and compatibility of this modular system was considered with a 4mm binding post socket.

It uses a standard plug-in profile panel for common use of all the training set. Each part could be horizontally or vertically attached and detached on the profile panel without any tools.

Features:

- Modular design allows modifications to suit needs/requirements of the course/students.

- Custom sizes for the modular-board can also be provided upon request.

- Additional modular components are also available separately should the need arise.

- High quality durable rubber-silicone compound gourmet on the modular-board ensures that the components stay in place yet smooth enough to ease removal and placement of components.

- Comes with high quality industrial grade components.

- Water Power Pack was designed to ease handling and transportation

- Comes with Water Power Pack with built-in high power 350W water pump for all your experiments needs.

- Comes with quick action self-sealing couplings and mounted ready for use!

- Plates are made of high quality machined steel that do not deform after continued usage.

- Unit comes with various height (tilt) settings

- Does not require hydraulic fluid but uses readily available water. This makes the unit very affordable and economical to maintain.

- High quality aluminum components that do not rust!

The Hydraulic Trainer has been designed to suit the theoretical and practical needs of Vocational Schools, Technical Training Institutions, Polytechnic and University. It is best suited as an introductory tool to hydraulics.

Circuit exercises that constructed with the unit are: –

Hydraulics Circuit Exercise:

| o Exercise 1: Directional Control – Double Acting Cylinder Control with 5/2 Way Directional Control Valve, Lever Operated.

o Exercise 2: Directional Control – Double Acting Cylinder Control with 5/3 Way Directional Control Valve, Lever Operated, Closed Center o Exercise 3: Speed Control by Using One Way Flow Control Valve o Exercise 4: Pressure Control by Using Pressure Regulator o Exercise 5: Metering “IN” and Metering “OUT” o Exercise 6: Automatic Forward and Backward o Exercise 7: Weight Loading by Using Spring Load

|

| Electro-Hydraulics Circuit Exercise: |

| o Exercise 8: Directional Control-Double Acting Cylinder Control with 5/2 Way Valve with Single Solenoid

o Exercise 9: Directional Control-Double Acting Cylinder Control with 5/2 Way Valve with Double Solenoid o Exercise 10: Speed Control by Using One Way Flow Control Valve o Exercise 11: Pressure Control by Using Pressure Regulator o Exercise 12: Metering “IN” and Metering “OUT” o Exercise 13: Automatic Forward and Backward o Exercise 14: Weight Loading by Using Spring Load |

Experiments Modules Lists:

| Item | Component | Description | Symbol |

| 1 |  |

(FW-100-00)

Experiments Plug Board Module Rubber Grommet Plug Points Built-In Metal Quick Coupler Pressure Port (Left Portion) Tank Port (Right Portion) |

1 Set |

| 2 |  |

(FW-100-01)

Double Acting Cylinder with Striker Cam used Vertically with Spring Weight Load |

1 Unit |

| 3 |  |

(FW-100-02)

Double Acting Cylinder with Striker Cam used Horizontally |

1 Unit |

| 4 |  |

(FW-100-03)

Pressure Reducing / Regulating Valve with Pressure Gauge |

1 Unit |

| 5 |  |

(FW-100-04)

Pressure Gauge |

2 Units |

| 6 |  |

(FW-100-05)

3/2 Way Directional Control Valve, Lever Operated Module |

1 Unit |

| 7 |  |

(FW-100-06)

5/2 Way Directional Control Valve, Lever Operated Module |

1 Unit |

| 8 |  |

(FW-100-07)

5/2 Way Valve with Pilot Bistable Module |

1 Unit |

| 9 |  |

(FW-100-08)

5/3 Way Directional Control Valve, Lever Operated, Closed Centre Module |

1 Unit |

| 10 |  |

(FW-100-09)

One-Way Flow Control Valve Module |

2 Units |

| 11 |  |

(FW-100-10)

3/2 Mechanical Valve Module Valve : Left x 1, Right x 1 |

2 Units |

| 12 |  |

(FW-200-01)

5/2 Way Valve with Single Solenoid Module (24 VDC) |

1 Unit |

| 13 |  |

(FW-200-02)

5/2 Way Valve with Double Solenoid Module (24 VDC) |

1 Unit |

| 14 |  |

(FW-200-03)

Electrical Roller Limit Switch Module Contacts : N.O. x 1, N.C. x 1 (Left) Contacts : N.O. x 1, N.C. x 1 (Right) |

1 Unit |

| 15 |  |

(FW-200-04)

Electrical Push Button Module Contacts : N.O. x 1, N.C. x 1 |

1 Unit |

| 16 |  |

(FW-200-05)

Electrical Selector Switch Module Contacts : N.O. x 1, N.C. x 1 |

1 Unit |

| 17 |  |

(FW-100-11)

T-Joint |

5 Units |

| 18 |  |

(FW-100-12)

Quick Coupler Plug |

6 Units |

| 19 |  |

(FW-100-13)

Hoses Diameter : 4 mm Length : 2000 mm |

1 Set |

| 20

|

|

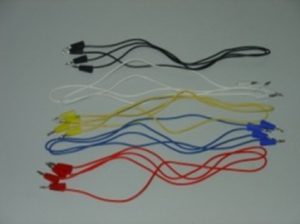

(FW-200-06)

Stackable Test Lead Set Quantity : 10 units (Black x 2, Red x 2, Blue x 2, Yellow x 2, White x 2) |

1 Set |

| 21 |  |

(FW-100-14)

Hydraulic Power Pack Module Dimensions (H x W x L) : 450 mm x 300 mm x 400 mm Weight : 19.44 kg without Water Power Output : 1.25 HP Flow Rate : 35 Liters per Minute |

1 Set |

| 22 |  |

(FW-200-07)

Portable Power Supply Unit Dimensions (W x H x D): 215 mm X 150 mm X80 mm Power Supply: 24 VDC 1.5A 4 Pairs of Safety Socket Terminals: 24 VDC x 4 3-Pin 240 VAC Power Cord |

1 Set |

| 23 |  |

(FW-202-01)

Softcopy Format Instruction Manual |

1 Set |

Note: Specification, Layout & Design May Change Without Prior Notices For Continuous Products Upgrading and Development Process.