ABOUT US

Welcome To Scienscope Sdn Bhd

Established since 2000, SCIENSCOPE SDN BHD is Malaysia’s leading solution provider for technical education training and laboratories equipment.

With our in-house assemble and with 100% quality inspection and quick response technical support, we ensure customers to receive the desired products with satisfaction. We are looking forward to being of assistance to you.

0

+

Products Available

Wide range of training and laboratories products available

Feature Products

Product Categories

-

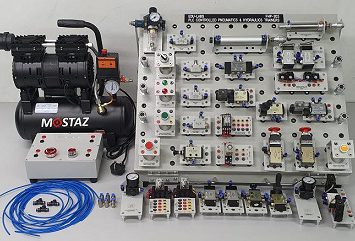

Pneumatics & Electro-Pneumatics Training System

2 products -

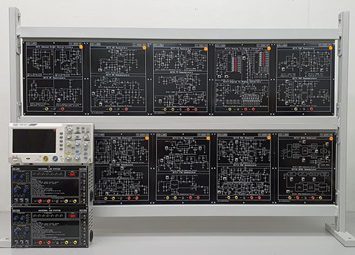

Main Switchboard Training System

10 products -

Motor Control & Starter Training System

8 products -

Power System Training System

5 products -

Electrical Machines Training System

35 products -

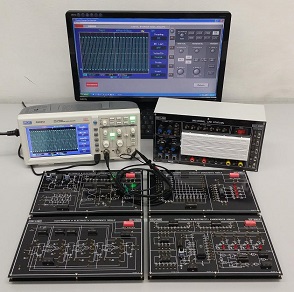

Consumer Electronics Training System

13 products -

Electronics & Electricity Training System

13 products -

Electrical Installation Technology Training System

2 products -

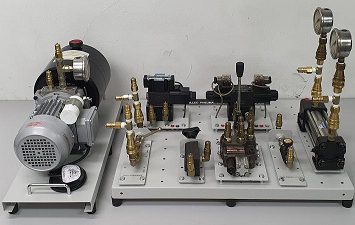

Hydraulics & Electro-Hydraulics Training System

19 products -

Green Technology Training System

1 product